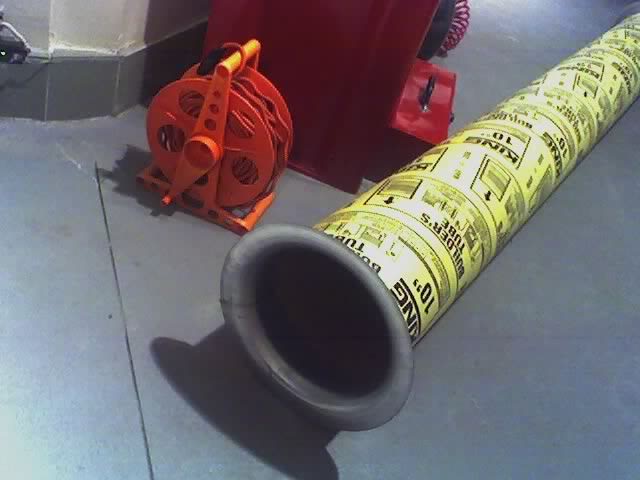

Stretch PVC to flaires

#1

Stretch PVC to flaires

And one think of a good jig to stretch PVC for port faces.out there are cheap and frail so I want to do my own from thicker PVC.

I can think of a few ways but its not much of a jig to keep them the same everytime so I wanted to see if someone has figure out something for a jig.

I can think of a few ways but its not much of a jig to keep them the same everytime so I wanted to see if someone has figure out something for a jig.

#5

find a metal funnel about the shape you want and use that for the jig.. might be hard to find something big enough, but you get the idea

to shape the pvc, heat up cooking oil in a pot, hold the end of the pvc that you want to flare in the oil long enough that it's bendy, then press it over the jig

to shape the pvc, heat up cooking oil in a pot, hold the end of the pvc that you want to flare in the oil long enough that it's bendy, then press it over the jig

#9

And one think of a good jig to stretch PVC for port faces.out there are cheap and frail so I want to do my own from thicker PVC.

I can think of a few ways but its not much of a jig to keep them the same everytime so I wanted to see if someone has figure out something for a jig.

I can think of a few ways but its not much of a jig to keep them the same everytime so I wanted to see if someone has figure out something for a jig.

doubt it...i don't want to even get into heating/bending pvc(a nightmare)....there are so many ways for it to go wrong.....just push it outta your mind....maybe follow yuli's advice.

well, since I'm already on the interweb, I'll devulge, At my work we wanted to bend 1/4" pvc into(2)90 degree bends.(sounds pretty simple eh?)

Apparently there is a machine you could buy that has a heated line(thick metal wire), my boss is hella cheap...so we made our own.

We bought 2 lines and sorrounded it with cement sheets(forget the actual name of the sruff)

we placed the flat pvc on the 2 heated wires for a determined time(off the wire about half an inch), from there immediatly into a wood jig to bend it and keep it bent for at least a minute.

These"factors" I was talkin about was the wire didn't stay at an exact temp, so sometimes bubbles formed on the pvc, sometimes the pvc wasn't heated enough and didn't want to stay at a perfect 90 after it was takin outta the jig. The heater element was getting too hot over time and was burning the tables under it. The boss always wanted "faster" so doing 4 at a time was the way it was being done.

I think we went about it in a rushed sort of way(always the way at my work....and I'm sure most of yours as well)

as for suggestions, I have none, Flaring pvc pipe sounds like something that a special machine would have to do.